Our Technology

By using Meva Energys unique gasification technology to convert low value biomass residues in to renewable energy at site, a local, circular energy system can be created.

djdj

About our technology and how it works

Whether with wood-based feedstock or agricultural residue, our technology can be applied with many different industries.

Learn how it works and how it integrates with residues sources and energy needs in this short film.

About our technology and how it works

Learn how it works and how it integrates with residues sources and energy needs in this short film.

HIGH EFFICIENCY WITH LEAN BURN ENGINES CONVERTS BIOGAS TO POWER.

Meva’s technology is the only gasification system in the world being able to use lean burn CHP engines. The continuous and stable character of the process ensures that the gas supply exhibits extremely small level of variation.

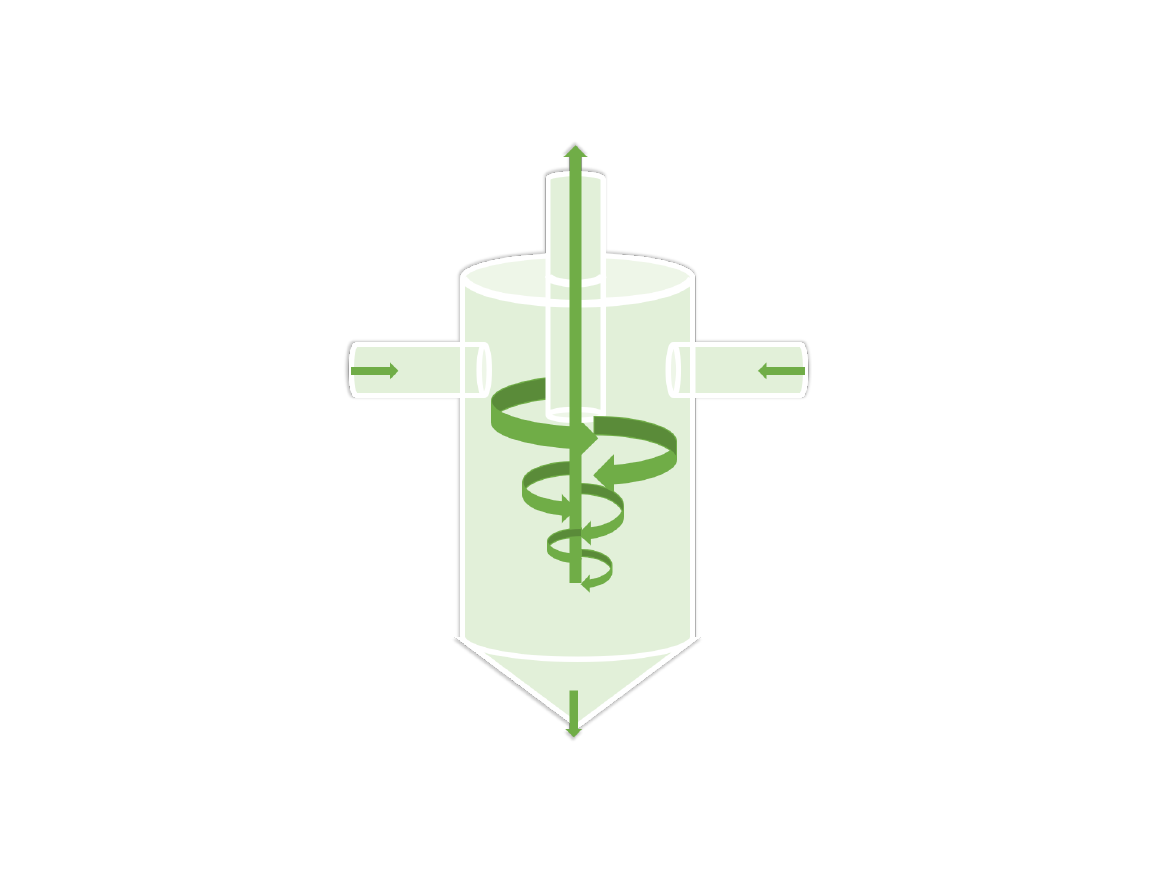

WITH A UNIQUE GASIFICATION TECHNOLOGY WE TURN IT INTO A CLEAN AND STABLE FUEL

MEVA ENERGY PRODUCES FUEL SUITABLE FOR INDUSTRIAL USE

- Full flame stability with 100% Biogas (no LPG enriching)

- Very low levels of particles in the exhaust gases

- No traces of odors or visual imperfections

- Functionality with several standard burner types such as: corner-, duct- and swirl burners

- Possible to co-fire LPG/NG and renewable Biogas in the same burner

- No need to redesign or expand existing burner chambers

- All results verified by Swedish research institute, RISE

"Meva Energy´s ability to valorize biomass waste streams and to produce a renewable biogas which substitutes fossil gas in industries is an excellent example of how an abundant residue resource can be used to reduce carbon emissions."

WE DELIVER A TURNKEY SOLUTION – IMPLEMENTATION AT PRODUCTION SITE

- Three steel skids, preassembled before being shipped to site

- Modularized design three modules with main vessels outside.

- Compact size - 13 * 3* 2,5 m skid size

- Consumes 1 ton biomass/hour

- Production

- 4,5 MW gas and 1 MW heat

- 50 kg biochar/hour

Sofidel, Kisa plant

AWARD WINNING TECHNOLOGY FOR CO2 REDUCTION

- Finalist “Low Carbon Energy production” in SET Awards (German Energy Agency)

- Solar Impulse efficiency label

- First prize winner EU-China Cleantech Competition at CleanConnect in Nanjing/Shanghai.

- Evaluated and eligible for project financing by European Investment Bank, EIB.

- Finalist for Sweden’s most prestigious award for climate innovation - E-PRIZE.

Short and Sweet Headlines are Best!