Green furniture production,

20,000

Tons CO2 reduction/year

2,8

MW Renewable power

2026

Startup

The Home of Tomorrow

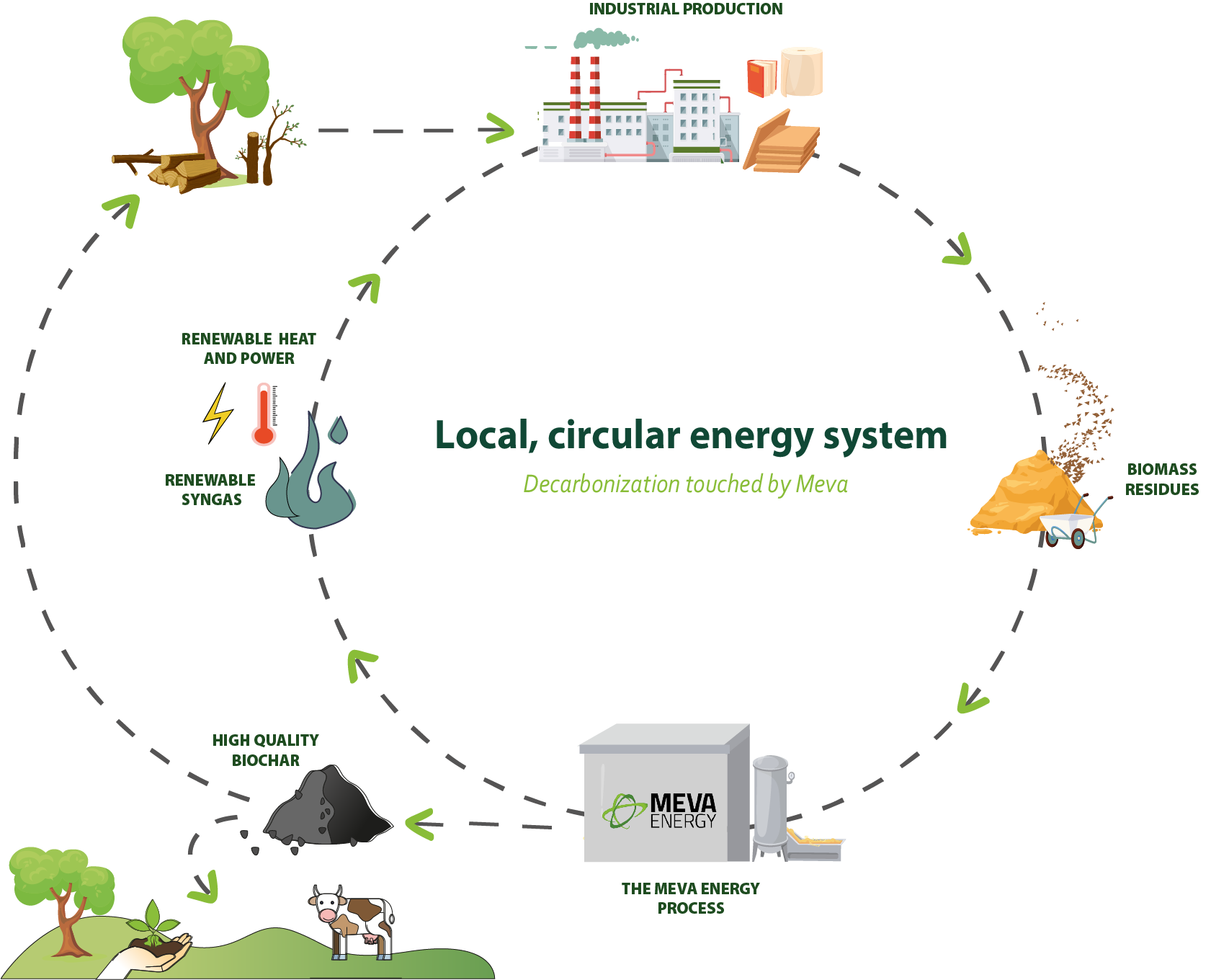

Industrial production processes, such as engineered wood and furniture manufacturing generate large amounts of fine fraction biomass residues. Meva Energy’s thermochemical conversion technology converts biogenic waste streams such as sawdust and residual fiber from MDF and chipboard production into renewable, green gas. The gas can then be used to run a power plant or to replace fossil gas in an industrial application. The system also produces biochar, a stable form of carbon that can be for example be used for soil improvement, thereby creating a carbon sink in the soil.

Learn more

IKEA industry: Shaping the future of furniture production

FROM WASTE TO PROFIT!

By using Meva Energys unique gasification technology to convert low value biomass residues to renewable power at site and a local, circular energy system can be created.

Fighting EMISSIONS

Learn more