Wood board products/waste containing glue typically contains high levels of solid nitrogen which when burned, can cause hazardous NOx4 and particulate emissions. Due to the low levels of oxygen and the high temperature in Meva Energy’s gasification technology, the nitrogen oxides can be kept low and convert the solid nitrogen in the process to harmless nitrogen gas.

When machining, such as grinding, sawing, milling, etc. board materials (construction wood/engineered wood, EW) such as MDF (Medium Density Fibreboard) and chipboard, the wood fibers are shortened and only a small proportion can be recycled into new board materials without the properties deteriorating too much. The adhesive in these products also contains solid nitrogen which is converted into hazardous NOx emissions during combustion. NOx emissions may not get quite the same attention as carbon dioxide, but they can pose serious health and environmental risks.

“NOx can lead to serious health risks humans because the small particles attack our respiratory organs. Nitrogen oxides can also contribute to acidification and eutrophication in our nature and thus cause damage to plant and animal life both on land and in water. Reduction of all NOx emissions are necessary for environmentally sustainable development and to keep the ground-level ozone at low level”, says Sara Palander, Sustainability manager at Meva Energy.

FOCUS ON COMBUSTION MANAGEMENT

Meva Energy’s entrained flow gasification technology is suited to take advantage of this finely fractionated residual stream from EW processing, where the solid nitrogen from the adhesive is instead converted in the process to harmless nitrogen gas. Solid nitrogen from the urea-based glue in wood panels is effectively being taking care of in the gasifier and in the gas cleaning system. The solution for improving combustion management and consequently reducing the formation of NOx in the boilers was developed in Meva Energy’s demo plant in Piteå. Read more about our technology here.

PRIZE WINNING TECHNOLOGY

Looking closer into the furniture and board production, the processing of MDF boards generates a lot of MDF dust. This low qualitative fine fraction dust means it can not be used in all types of boilers and burners. It can not be re-introduced in new boards either, only a small precentage of it.

The main issue within MDF is the glue, because in there you have solid nitrogen. By combusting the solid nitrogen, it turns into NOx emissions. Tougher NOx regulations means that for instance a furniture manufacturer can not utilise as much wood dust as they want to. So what Meva Energy do instead, is that we gasify this MDF dust to get nitrogen that can go through a combustion process and then go out into/enter the air. In the process, a small fraction of the nitrogen can form ammonia depending of the process parameters.

”Ammonia is partly captured in our gasification system so only part of it proceeds to the combustion process. Then in turn, only a very small share of that is converted into NOx emissions. So instead of having 100% of that extra NOx emissions, you only get up to 3%, which is extremelylow” explains Thomas Bräck, Business Development Manager at Meva Energy.

Utilizing MDF dust in such an effective way is the main reason Meva Energy received the ”Bois Energie d’argent prize 2020″.

”Imagine if you can have biomass residues that are low value to no value, and you can utilise that for high quality energy. Then you can get a local, circular energy system with really good cost efficiency”, Thomas Bräck continues.

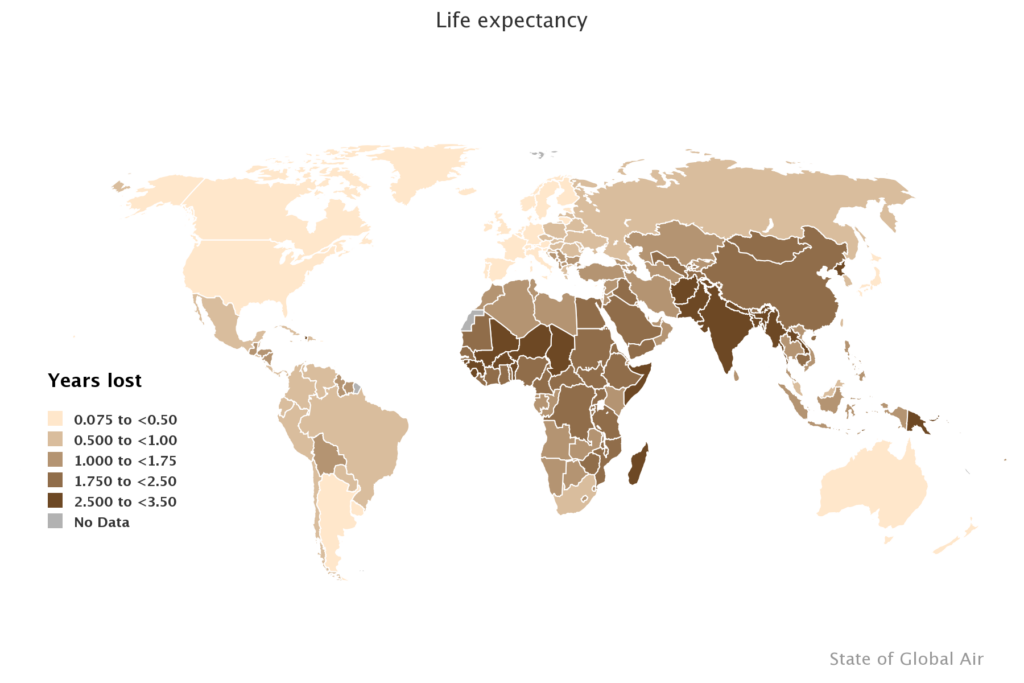

PROLONGING LIFE

In 2019, air pollution shortened average life expectancy by 1 year and 8 months according to the State of Global Air report[1]. Air pollution is a major health concern also for Europeans. In 2020 in the European Union, 96% of the urban population was exposed to levels of fine particulate matter above the health-based guideline level set by the World Health Organization. In 2020 exposure to concentrations of fine particulate matter above the 2021 World Health Organization guideline level resulted in 238,000 premature deaths in the EU-27. Air pollution also causes morbidity, whereby people live with disease — entailing both personal suffering and significant health care costs.[2]

The primary source of particulate matter, both PM10 and PM2.5, was energy consumption in the residential, commercial and institutional sector in 2020 according to European Energy Agency[3]. It was responsible for 44% and 58% of emissions, respectively. The manufacturing and extractive industry were also significant sources of both pollutants, even a bigger share than road transport sector.

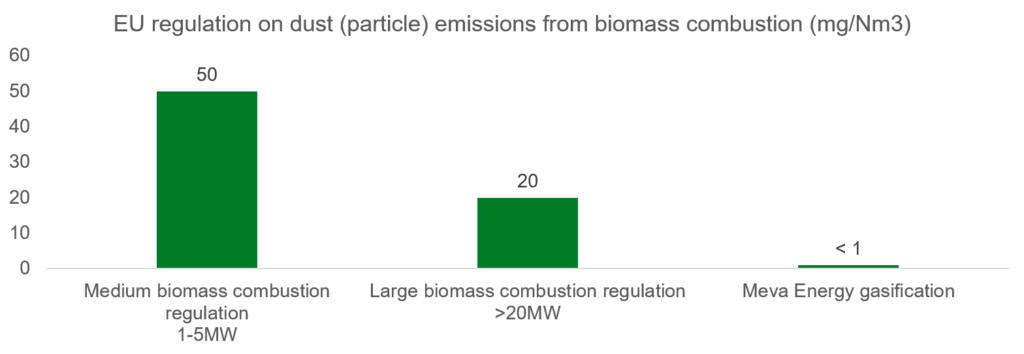

Meva Energy can make a difference by improving the energy generation for both facilities and the manufacturing industry. By using Meva Energy’s gasification and gas cleaning technology before combusting, a more complete combustion can be achieved and eliminate the issue with particulate emissions. The following chart can be used to illustrate this. Today, a biomass combustion plant in EU is allowed to emit 50 mg/Nm3 ( 20mg/Nm3 for large plants) while combustion of Meva Energy’s syngas from the same biomass while generate less than 1 mg/Nm3.

Sources:

- [1] EEA, Contributions to EU-27 emissions of BC, CO, NH3, NMVOCs, NOX, primary PM10, primary PM2.5, SO2 and CH4 from the main source sectors in 2020 https://www.eea.europa.eu/publications/air-quality-in-europe-2022/sources-and-emissions-of-air#:~:text=44%25%20and%2058%25

- [2] EEA, Air quality in Europe 2022, https://www.eea.europa.eu/publications/air-quality-in-europe-2022

- [3] EEA, Contributions to EU-27 emissions of BC, CO, NH3, NMVOCs, NOX, primary PM10, primary PM2.5, SO2 and CH4 from the main source sectors in 2020 https://www.eea.europa.eu/publications/air-quality-in-europe-2022/sources-and-emissions-of-air#:~:text=44%25%20and%2058%25

- [4] Nitrogen oxides (NOx) NOx is a collective term for nitrogen monoxide (NO) and nitrogen dioxide (NO2). NOx arises when fuel is burned at high temperatures, but the amount depends on the combustion method and plant design, as well as the nitrogen content in the fuel.

- https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32015L2193

- https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32010L0075