RESPONSIBLE BUSINESS

We are committed to conducting our business in a responsible and sustainable manner, striving to leave a positive impact on everthing that is touched by Meva Energy.

The manufacturing industry today accounts for large emissions of greenhouse gases and is heavily dependent on fossil resources. A change is needed to reduce the industry's climate footprint. This is where we can make the greatest impact as a company. But also, we need to understand the impact that our own activities and decisions give rise to. It’s about how we act and behave across our entire value chain.

To leave a positive impact on everthing that is touched by Meva Energy, we focuse on three key areas:

A circular solution that generates negative emissons

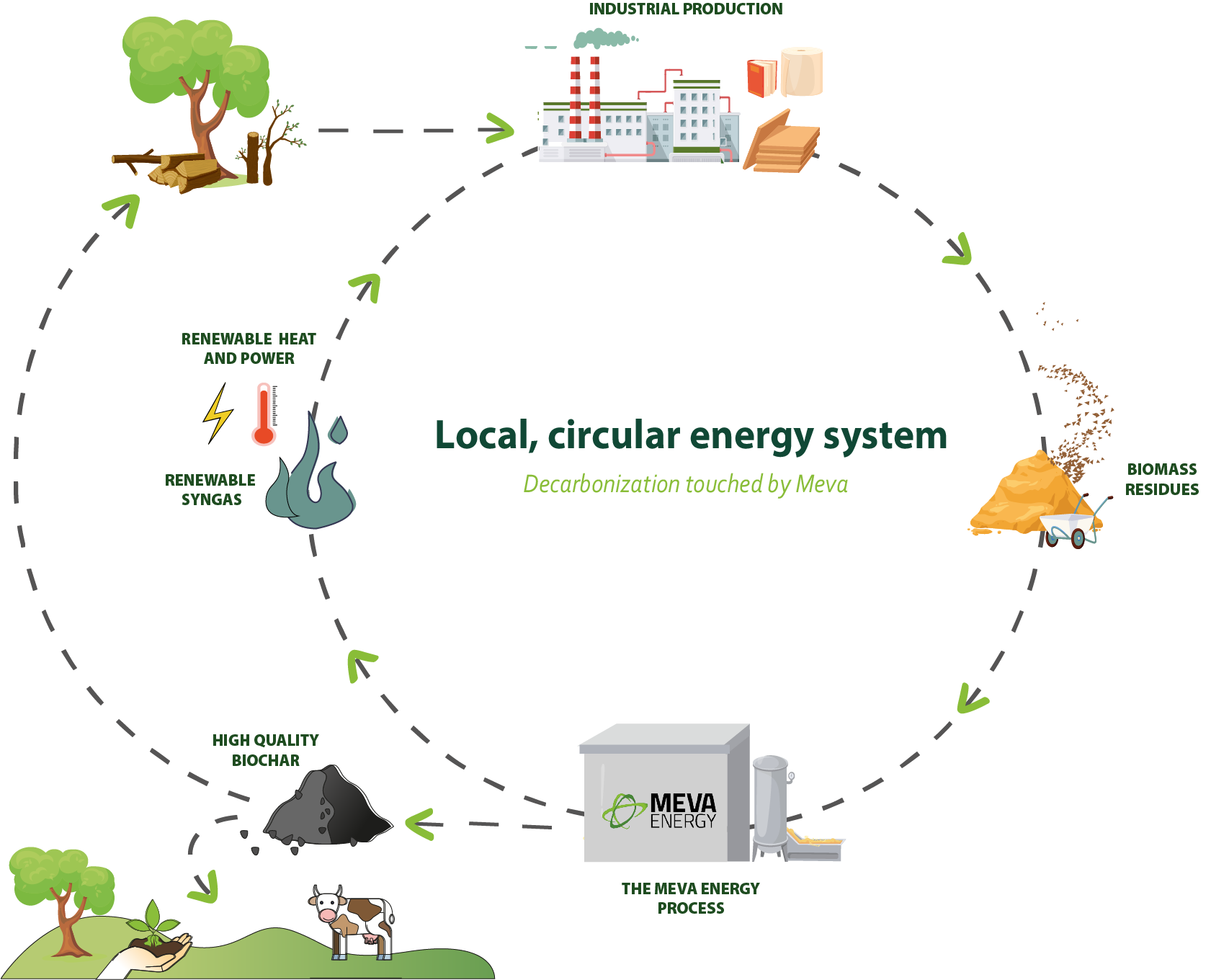

Energy production is the company's most important sustainability metric and is crucial to mitigating climate change. Meva Energy's purpose and business is to deliver renewable energy to customers. By making better use of local residual waste from the manufacturing industry, such as low-quality biomass into high-quality biogas at the production site, greenhouse gas emissions are significantly reduced.

In the gasification process, when biomass is heated into a high temperature in an oxygen-controlled environment, biochar is being produced. Biochar is a very porous material with a large surface area and high carbon content. Research shows that biochar contains a very stable form of carbon and therefor acts as an important technology for removing carbon dioxide from the atmosphere, called Biochar Carbon Removal (BCR). This means that a gasification plant not only produces renewable biosyngas for customers and climate benefits but also yields additional advantages through biochar.

"We believe in a fossil free manufacturing industry where no resources are wasted, and no fossil emissions are created."

Where does our fuel come from?

The strategy of Meva Energy is to use locally existing biogenic waste streams (a low-quality fine fraction of waste) as feedstock for Meva's plants. There are two reasons for this focus:

-The low economic value of such feedstock streams driver of operational plant profitability

-The waste character means that the feedstock has reached its end-of-life and that recycling no longer is an option. Local high-efficiency conversion to power or natural gas substitute is then the sustainably most attractive option of all. The alternative (that e.g.. IKEA is applying today) is most often to incinerate it in co-generation incineration plants.

Providing a technology that involves the use of biomass relates to risks such as land use change, deforestation and biodiversity loss. Biomass needs to be sustainable utilized, where material, pulp and paper and fibers are prioritized applications and energy applications are using second generation waste, generated from the manufacturing industry. Meva Energy's gasification technology is optimized for utilizing low-value and fine fraction biomass, which makes it possible to use e.g. contaminated engineered wood classified as waste as a feedstock to the gasification process.

Sustainable biomass feedstock policy

This policy states the importance of a sustainable use of biomass residues and waste and our responsibility in evaluating available feedstocks based on all three dimensions of sustainability. Another important part of this policy is to secure a sustainable feedstock used by our customers, through warranties.

Responsible sourcing

When purchasing biomass, the procurement process includes some evaluation criteria, such as presence of independent certification of biofuel, (certified through FSC or PEFC), distance from the operation, and presence of Sustainability Certificate (Sustainability Criteria Act / RED certificate).

Sustainability certificate

This Sustainability certificate, serves as a proof that the managed and produced biofuels meet established criteria under the Law on Sustainability criteria for biofuels, bioliquids and biomass fuels and according to the Renewable Energy Directive, including nature protection purposes, greenhouse has emissions savings, transparency and traceability.

We take action against land use, change and deforestation

To manage the risks related to deforestation, land use change and biodiversity losses we have established and implemented a Sustainable biomass feedstock policy, updated our Sourcing strategy, and certified our plant according to the Swedish Criteria Act (Sweden's implementation of RED).

Reducing emissions from our operations

With a vision for a fossil-free manufacturing industry, understanding our products' climate impact is crucial. Meva Energy conducts greenhouse gas emissions calculations for all new projects. The Kisa plant enhances precision in these calculations, revealing activities with the highest climate impact. This insight guides our gasification plant operations.

Greenhouse gas emissions calculations adhere to Sweden’s implementation of the EU Renewable Energy Directive (RED). hese calculations, verified independently,

we contribute significantly to a sustainable society

Local air pollution and health impacts

In all our projects, NOx1 and particulate emissions needs to be controlled and managed to secure low levels from combustion. This is part of the early product development and quality control from our projects. In biosyngas application for process heating NOx and particles are being emitted by our customers. Depending on the biomass feedstock and how the feedstock has been treated plays an important role in how the gasification plant needs to be run in order to reduce emissions to air, among other things.

In wood board products and waste containing glue typically contains high levels of solid nitrogen which when combusted, can cause hazardous NOx and particulate emissions. Due to the low levels of oxygen and the high temperature in Meva Energy’s gasification technology, the nitrogen oxides can be kept low and convert

the solid nitrogen in the process to harmless nitrogen gas. Meva Energy’s entrained flow gasification technology is suited to take advantage of finely fractionated residual stream from engineered wood processing, where the solid nitrogen from the adhesive is converted in the process to harmless nitrogen gas. Solid nitrogen from the urea-based glue in wood panels is effectively being taking care of in the gasifier and in the gas cleaning system. The solution for improving combustion management and consequently reducing the formation of NOx in the boilers was developed in Meva Energy’s demonstration plant in Piteå

Learn more about how we are fighting NOx and particulate issues in engineering wood production here.

Diversity, equity and inclusion

Meva Energy’s performance as a company is based on the employees’ performance as individuals, a healthy company with possibilities for development are strong driving forces.

Diversity, equity and inclusion means a workplace free from discrimination and ensuring that all employees have access to the same resources and opportunities at the company, without regard to such parameters as gender, marital or parental status, ethnic or national origin, sexual orientation, religion or beliefs, political affiliation, age, or disability. In the newly established Diversity, equity and inclusion policy, the company states to take responsible and conscious actions and decisions towards an equal and fair workplace. Working actively with diversity, equity and inclusion will benefit the company and its ability to become more innovative, visible and attractive for employees, customers, suppliers and investors.

Supply chain Best!

Policy documents and internal practices have been developed to create common statements for anti-corruption and bribery, respect for the human rights of employees, prohibition of child labor, health and safety of employees, environmental protection, supply chain. Working practices in the company's purchasing processes and in the supplier evaluation processes have been established. Supplier evaluations are done partially, depending on size and type of business deal. We are using an external service to access third party risk and compliance data in the evaluation process, including elements of ESG data.

Sustainability reporting

Our sustainability work is an integrated part of our daily business. Therefore, we have also chosen to integrate our sustainability report into the annual report.

Sustainability report download