Renewable, local power & heat production

Meva’s CHP plant generates renewable, comnbined heat and power (CHP) directly on site, making it an effective replacement for fossil energy in industrial production processes, aiming to reduce emissions and fuel costs.

Key benefits of Meva's CHP solution

Significant CO2 reduction

Meva’s power and heat are generated from renewable biosyngas, enabling you to replace fossil gas and significantly reduce your carbon footprint

Stable and competitive energy cost

Say goodbye to price spikes and carbon taxes. Meva’s pricing model is tied to biomass and inflation, giving you predictable costs and long-term energy security

Reliable, on-site energy supply

Secure your energy independence. Biomass can be sourced locally or globally, ensuring a steady, resilient supply for continuous operations

Industrial scale, decentralized production

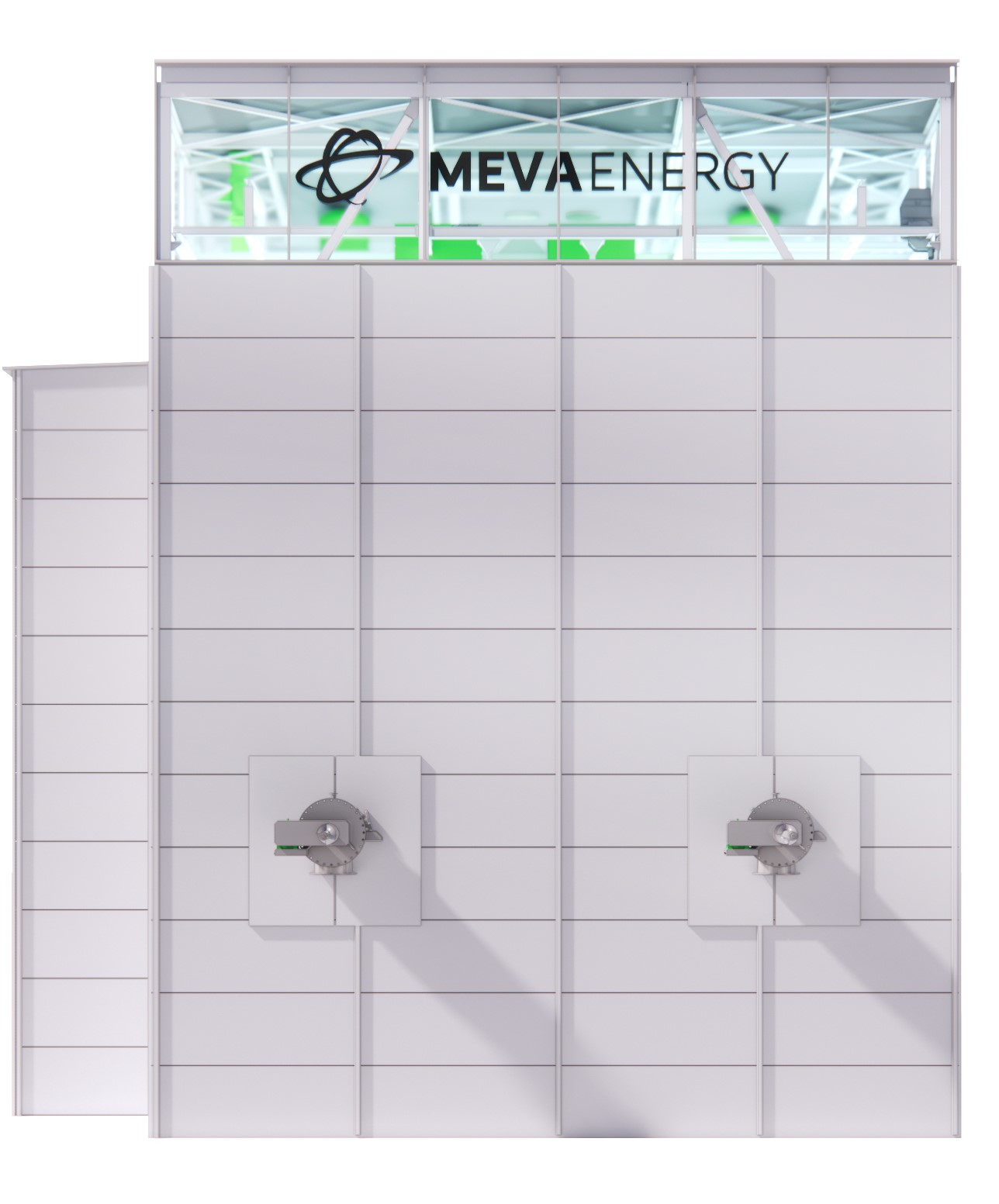

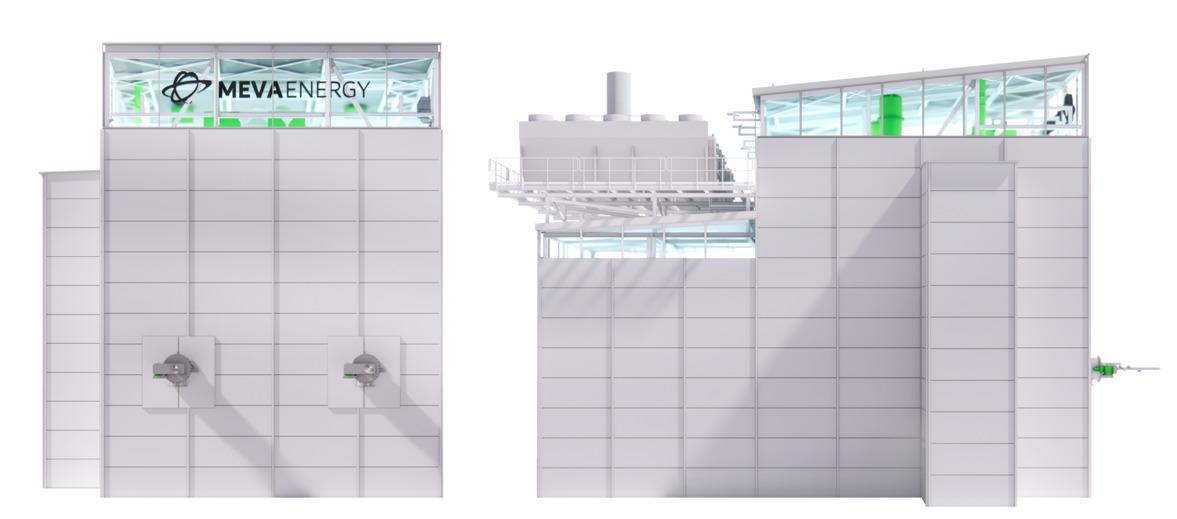

We produce the energy right where you consume it. Meva’s modular gasification units enable efficient, on-site energy production tailored to your specific industrial needs. By decentralizing production, we reduce energy losses and transportation costs while increasing reliability and flexibility. This approach supports sustainable industrial processes with minimal environmental impact and no need for large upfront investments.

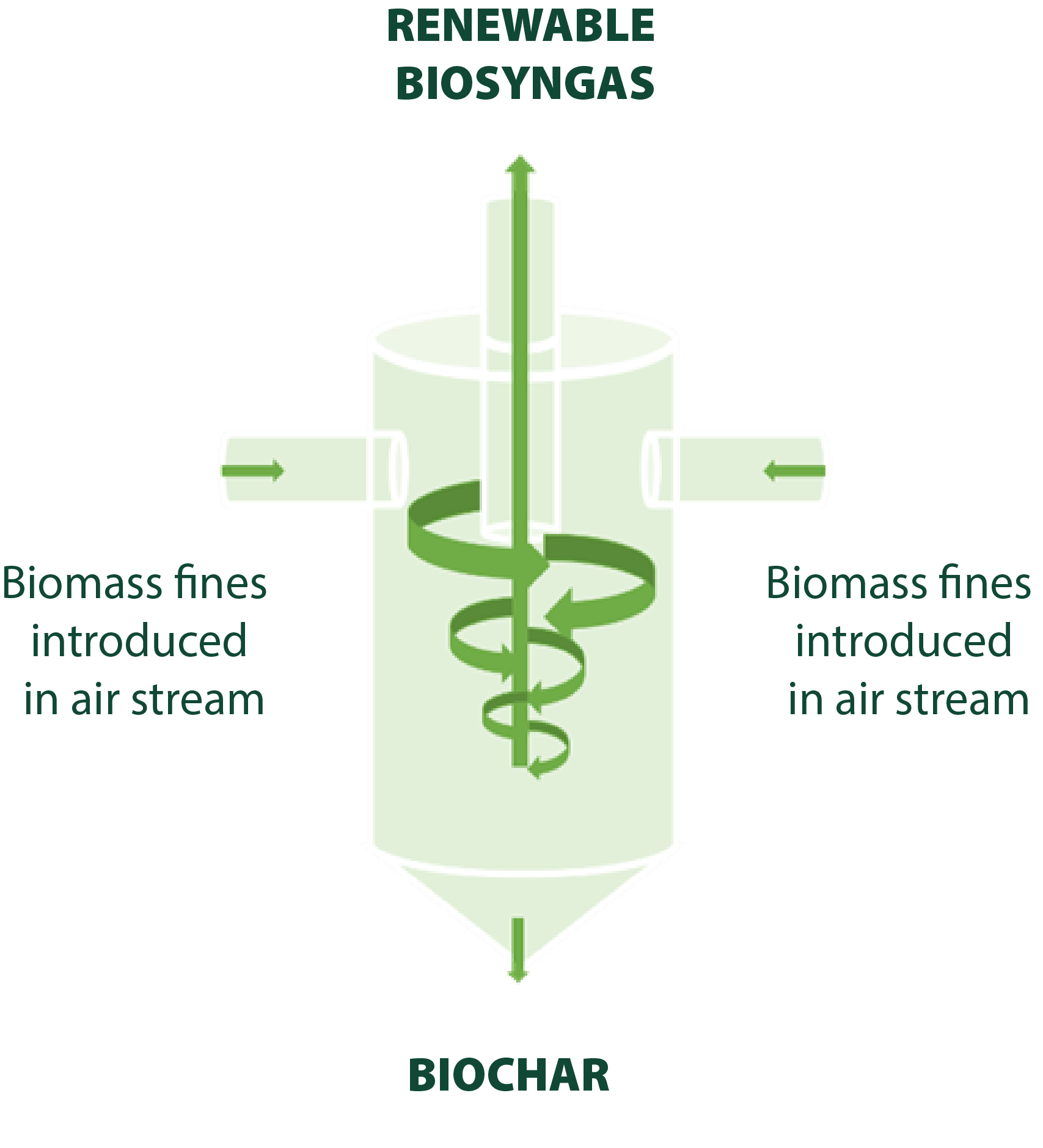

Thermal gasification converts fine fraction biomass into clean, stable gas

Our thermal gasification technology converts fine fraction biomass residues into clean, stable gas on site, ensuring a reliable and efficient energy supply. At the heart of Meva’s technology is a high-temperature reactor operating in an oxygen-deficient environment, which continuously processes biomass with minimal variation in gas quality. This advanced entrained flow principle allows for rapid gasification and high output from compact feedstock volumes.

Our technology >

Customer Cases

Specifications

Application: Power and Heat

Gas capacity: Minimum of 1.4 MW electricity

Biochar production: from 400 ton/year

CO2 reduction potential: 20 000 ton/year

Feedstock: Industrial biomass residues

Standard plant area: 20x39 m

Industry applications: Wood and furniture

Contract: Energy Purchase Agreement (EPA) or Turn Key solution.

Application: High temperature heat

Gas capacity: 4,5 MW and upwards

Biochar production: from 400 ton/year

CO2 reduction potential: 10 300 ton/year

Feedstock: Industrial biomass residues

Standard plant area: 20x39 m

Industry applications: Metallurgy, Lime, Ceramics and glass, Concrete

Contract: Energy Purchase Agreement (EPA) or Turn Key solution.

Application: High quality process heat

Gas capacity: 4,5 MW and upwards

Biochar production: 400 ton/year

CO2 reduction potential: 10 300 ton/year

Feedstock: Industrial biomass residues

Standard plant area: 20x39 m

Industry applications: Tissue drying

Contract: Energy Purchase Agreement (EPA) or Turn Key solution.

Peter Kvist, Sales Manger, CHP

How do you see your energy supply in the future?

Reach out to our hot gas expert Peter to discuss how our gasification technology can help lower emissions in your production. We’ll work closely with you to provide customized calculations and feasibility studies, ensuring a solution that fits your specific needs. From the initial assessment to full implementation, we’ll be there to guide and support you every step of the way.