OUR TECHNOLOGY

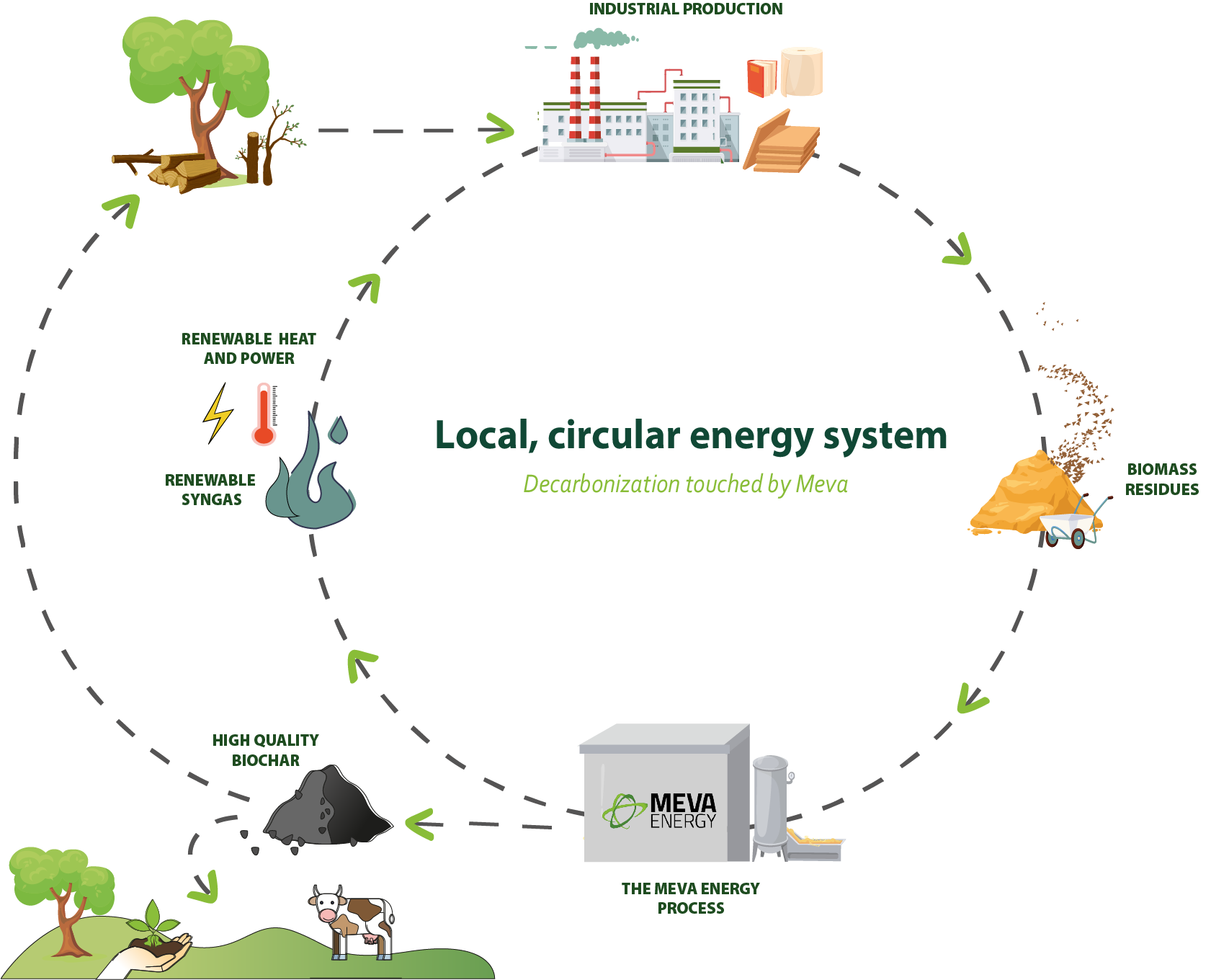

Meva Energy’s vision is to enable a fossil-free manufacturing industry, where biomass residues and biowaste is converted into biosyngas which is used to replace fossil fuels. Our process is characterized by having a high process efficiency, ensuring that no biomass resources are wasted and no fossil fuel emissions are created. This is how it works:

From biomass residue

By gasification

To energy

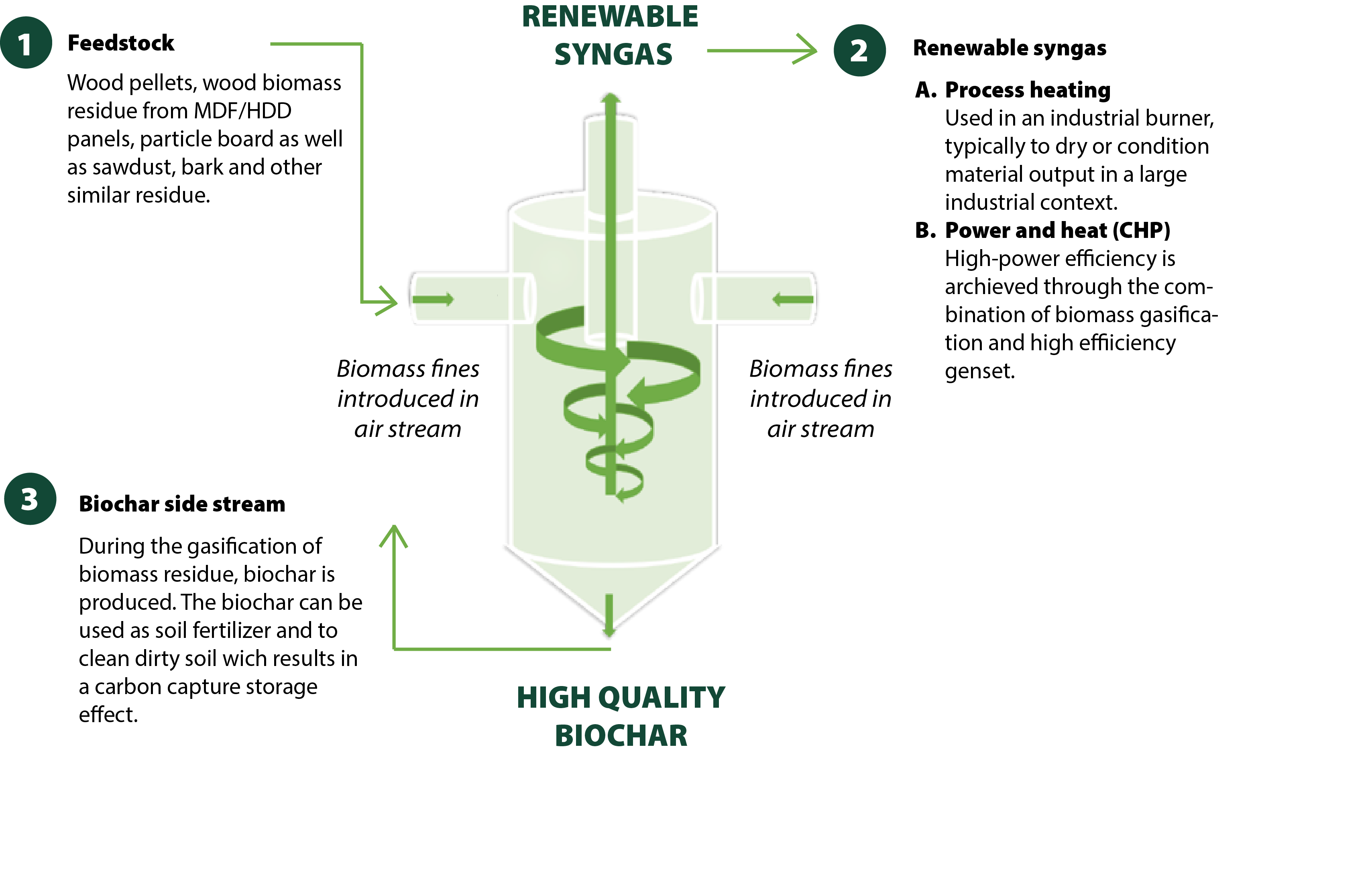

Industries that process solid biomass such as wood also generates large amounts of fine fraction biomass residues. We utilize this waste as a resource.

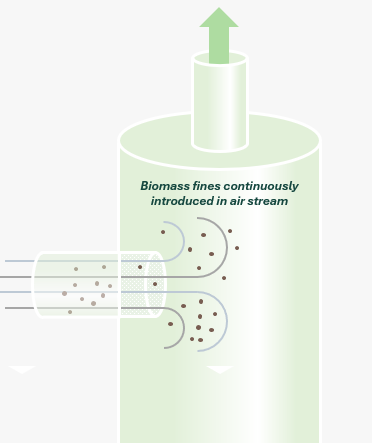

The biomass fractions are heated in an oxygen-limited environment, a process known as thermochemical gasification. This converts the solid biomass into a clean, energy-rich gas called Biosyngas, primarily composed of hydrogen, carbon monoxide, and methane. In parallel, the process produces biochar, a stable, carbon-rich by-product.

The gas is used directly by our customers to replace fossil gas in industrial processes. It can also be converted into electricity or combined heat and power (CHP) via a generator. The biochar serves as a soil enhancer, a permanent carbon sink, or a fossil carbon substitute in metallurgical applications.

Biomass: a reliable energy stream from nature

Biomass gasification is a circular energy technology that transforms organic residues from agriculture, industry, and forestry into clean energy. These biomass feedstocks are part of natural and industrial cycles continuously generated, collected, and reused, creating a closed-loop system that minimizes waste and maximizes resource efficiency.

Because biomass is produced predictably throughout the year as part of these ongoing cycles, the supply is reliable and consistent. This makes biomass gasification a dependable and cost-efficient source of renewable energy.

What is Biosyngas?

Biosyngas is a renewable gas consisting of carbon monoxide (CO), hydrogen (H₂) and minimal methane. It offers a significantly lower climate impact compared to fossil alternatives like LPG, without compromising on quality. Biosyngas can replace traditional fossil fuels in many industrial processes, making it an efficient and sustainable solution to reduce greenhouse gas emissions while meeting energy demands.

OUR GASIFICATION TECHNOLOGY TURNS RESIDUE INTO A CLEAN AND STABLE FUEL

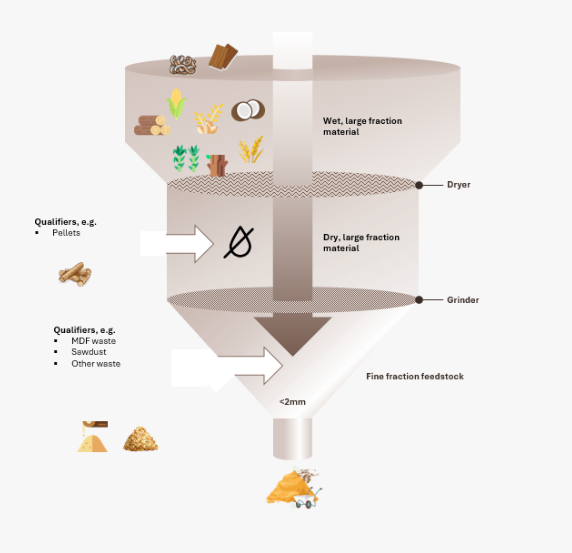

Full allowance of feedstock

- The system accepts larger biomass scrap, which is processed through a mill and/or dryer before being fed into the reactor. Some feedstock, such as MDF and sawdust, meets the requirements without modification

- Meva’s gasification process has a feedstock limit of <2mm and full acceptance of fine fraction feedstock

- Hence, the processing can be customised from the modular design foundation, in order to fit the customer’s biomass waste

- The allowance of fine fraction feedstock is because of the small size of the reactor itself

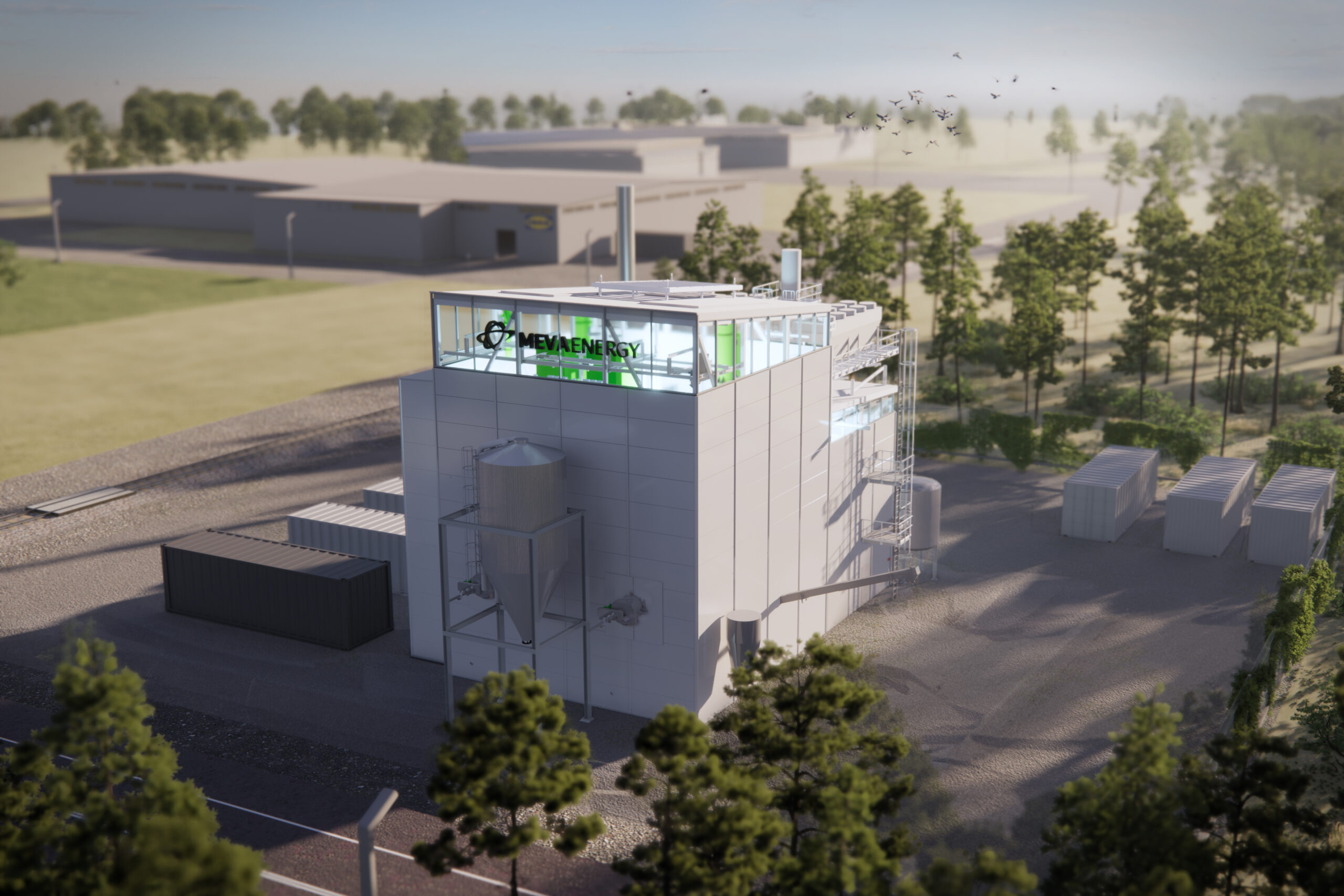

Our gasification plants are strategically located at our customer's site, where the energy is consumed.

Products

Effect

Application

4,5 - 15 MW

Metallurgy, Tissue drying, Lime, Concrete, Ceramic & glass

4,5 - 10 MW

Tissue drying

Wood and furniture

Production on site. On us.

Meva Energy offers both EPA and turnkey solutions. With an Energy Purchase Agreement (EPA), we build, own, and operate the renewable energy plant directly at your site. You simply purchase the energy it generates. No upfront investment, no operational burden—just predictable, low-emission power delivered where you need it.

Prefer to own the plant? Our turnkey solution puts you in control. We provide a fully customized, ready-to-run facility that integrates seamlessly into your production. You invest, we deliver—from design and construction to commissioning and support.

Peter Kvist, Sales Manger

You could to be carbon negative by 2030. Speak with us today!