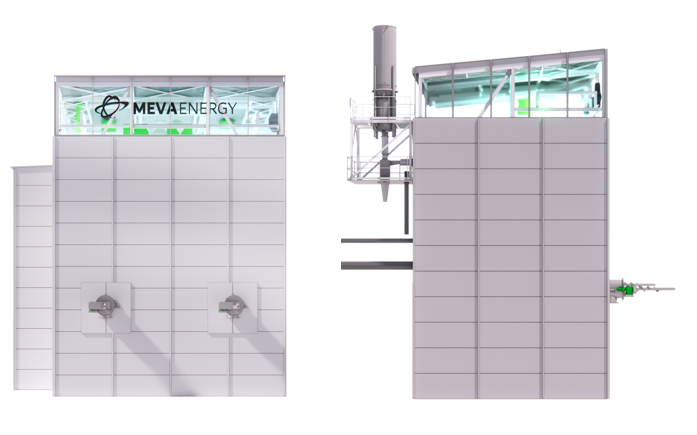

Industrial scale, decentralized production

We produce the energy right where you consume it. Meva’s modular gasification units enable efficient, on-site energy production tailored to your specific industrial needs. By decentralizing production, we reduce energy losses and transportation costs while increasing reliability and flexibility. This approach supports sustainable industrial processes with minimal environmental impact and no need for large upfront investments.

Peter Kvist, Sales Manger, Hot gas

How do you see your energy supply in the future?

Reach out to our hot gas expert Peter to discuss how our gasification technology can help lower emissions in your production. We’ll work closely with you to provide customized calculations and feasibility studies, ensuring a solution that fits your specific needs. From the initial assessment to full implementation, we’ll be there to guide and support you every step of the way.