Green Tissue production, touched by Meva

At Meva Energy, we’ve developed a technology that can effectively reduce CO2 emissions in tissue and paper production processes without compromising cost efficiency or operational performance.

WE PRODUCE BIOGAS SUITABLE FOR DIRECT PROCESS USE IN INDUSTRY

Meva Energy produces renewable biogas designed specifically for demanding industrial processes, such as tissue paper drying. Our technology offers a stable and consistent gas composition, ensuring the precise, high-temperature heat needed to maintain paper quality throughout the drying process. With minimal variations in gas flow and pressure, our biogas seamlessly integrates into your production line, offering a reliable, renewable alternative to traditional fuels.

ADDITIONAL VALUE WITH BIOCHAR

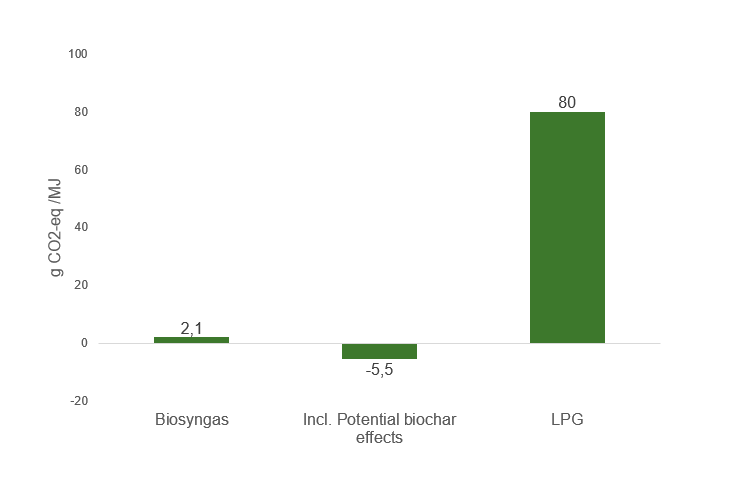

As a result of pure biomass gasification, high quality biochar is generated as a sidestream. Biochar can be utilized as a carbon sink, providing an opportunity to significantly reduce your carbon footprint. According to our latest LCA study, utilizing biochar can result in negative emissions, making your operations carbon-negative. Additionally, the biochar holds market value and can be sold as a product for various applications, turning an environmental benefit into a new revenue stream.

Read more about biochar and its additional value >

Tissue producer Sofidel cuts 10 000 tons CO2 annually with biosyngas at their Kisa mill

Renewable energy solution with negative emissions potential

Energy allocation

Carbon sequestration

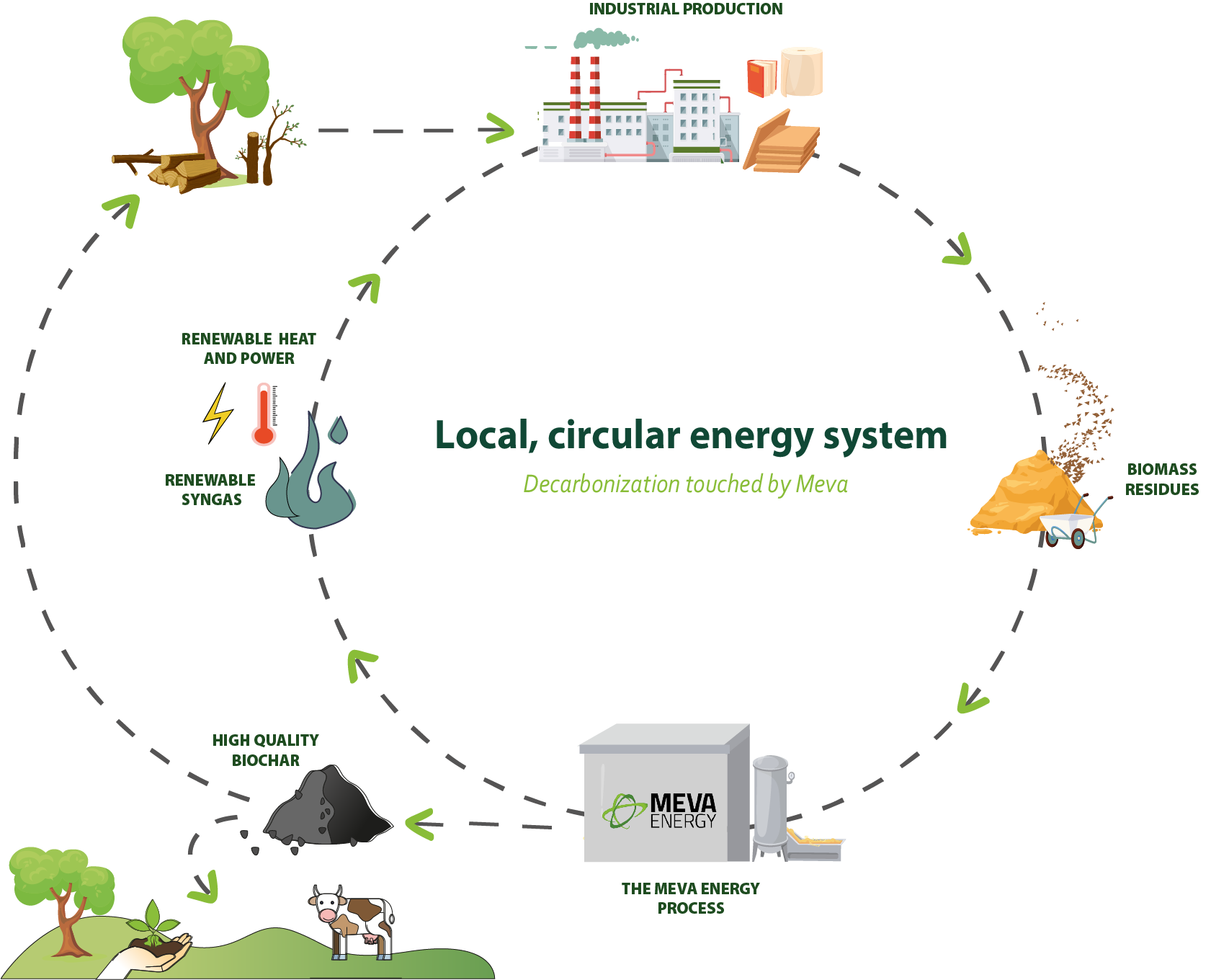

Meva Energy provides a gasification technology that can play an important role in the manufacturing industry’s shift towards renewable energy production. This technology utilizes locally generated biogenic waste streams from the manufacturing industry, converting low-quality biomass into high-quality biogas. By adopting this approach, the industry can mitigate climate change and significantly reduce fossil greenhouse gas emissions and customer’s carbon footprint. By the combined biogas and biochar production, the technology has the potential to go beyond zero and reach negative emissions.

Figure 1. The three allocation scenarios of Meva Energy’s biogas compared to fossil LPG (Hedbom, H and Lundh, P (2024).

Download our Life Cycle Assessment (1) A-potential-negative-emissions-technology-LCA-results.pdf (mevaenergy.com)

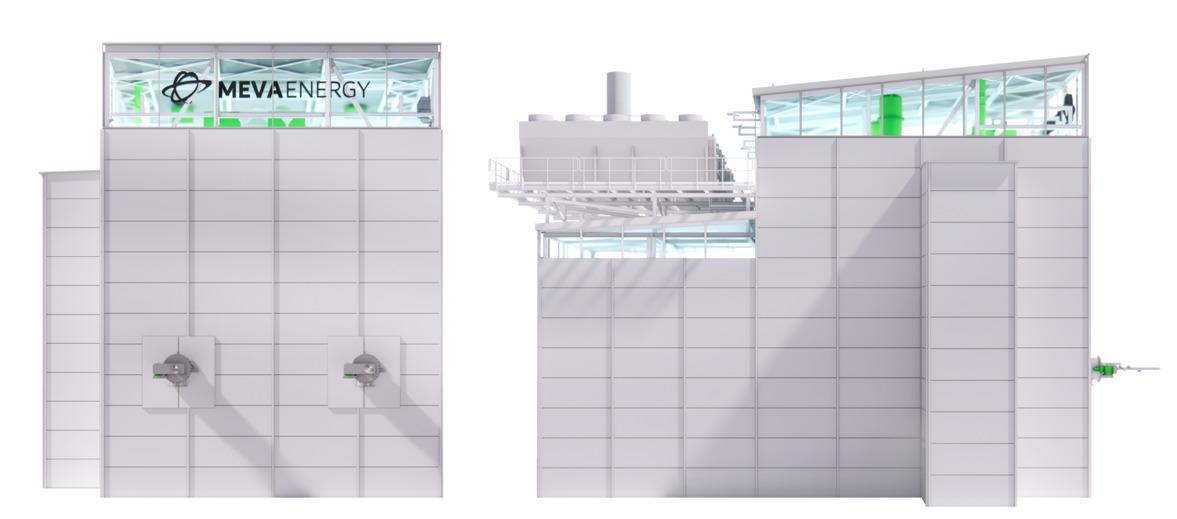

Site-built bioenergy plants

Application: High quality process heat

Gas capacity: 4,5 MW and upwards

Biochar production: 400 ton/year

CO2 reduction potential: 10 300 ton/year

Feedstock: Industrial biomass residues

Standard plant area: 20x39 m

Our modular plant design can easily scale to match the needs of different

tissue production sizes. Get a consultation >

what is biomass gasification?

Biomass gasification is a well-known thermochemical process for conversion of biomass into a biogas, consisting of mainly CO, H2, CO2, CH4 and N2. The resulting biogas can be used as a clean and efficient energy source, providing a sustainable alternative to traditional fossil fuels.

Utilizing local residues for renewable, cost-effective gas

Meva Energy’s technology converts low-value biomass residues such as sawdust or wood chips, into high-quality, renewable biogas directly at your production site. This localized, circular energy system reduces your dependence on external fuel sources, lowers transportation emissions, and offers a long-term energy solution.

Peter Kvist, Sales Manger, Tissue

How do you see your energy supply in the future?

Reach out to our tissue expert Peter to discuss how our gasification technology can help lower emissions in your paper production. We’ll work closely with you to provide customized calculations and feasibility studies, ensuring a solution that fits your specific needs. From the initial assessment to full implementation, we’ll be there to guide and support you every step of the way.